Overview

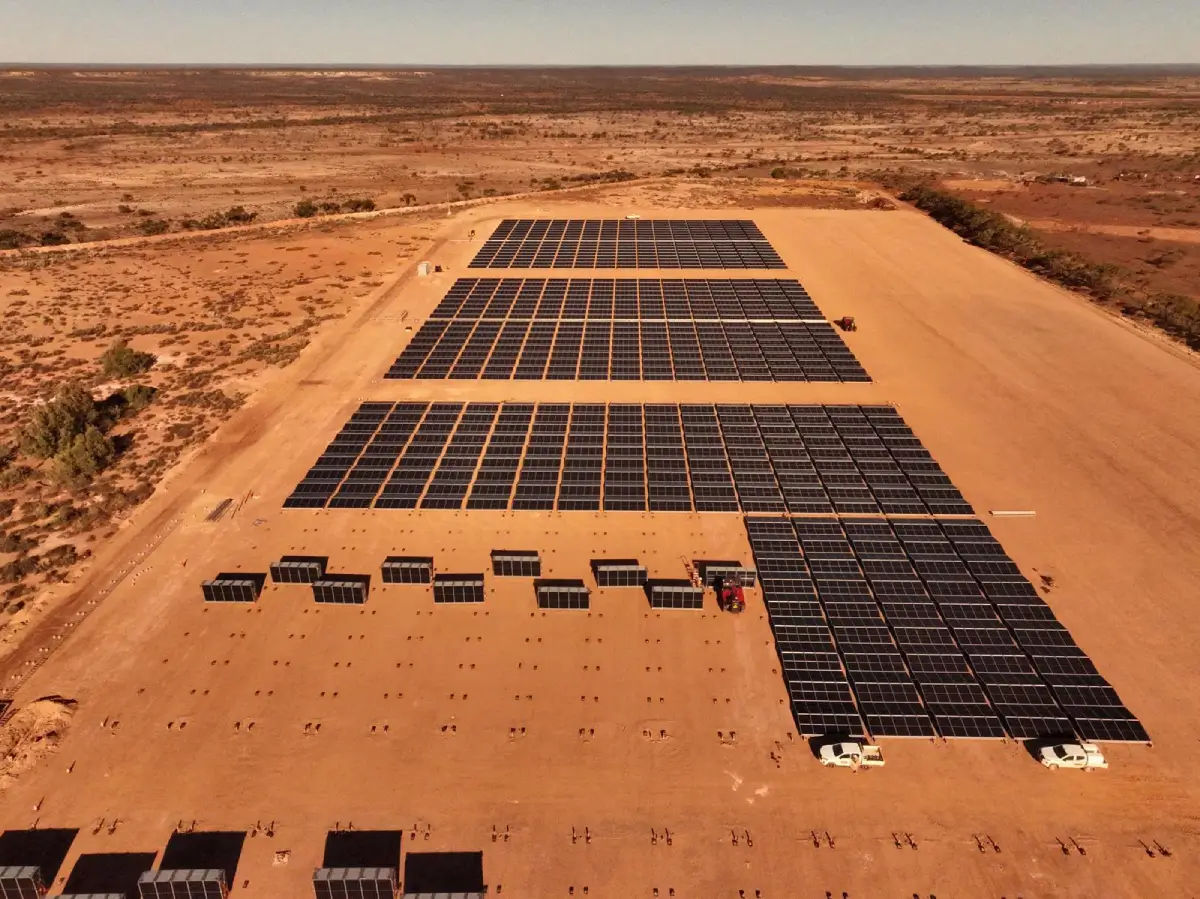

The Mt Magnet Gold Mine operation required an expanded power station to support increased mine operations and reduce reliance on fossil fuel power generation.

The new, hybrid power station includes 7MW of installed fixed panel arrays and 11MW AC capability across two central inverters, providing support for further expansions in the future.

Services Provided

PV Array Project Engineering and Installation:

- Project Management

- Site and schedule planning

- On site installation services for electrical and mechanical PV array deployment

- DC cabling installation and terminations

- Construction verification and commissioning

Highlights

- Achieved first power targets despite various schedule impacts and external delays

- Proved deployment methodology at scale for first major SGC Australia solar deployment

Our Involvement

Partnering with 5B, our scope of works covered the deployment of the 5B Maverick 3.0 fixed panel solar array, totalling 127 mavericks of 90 solar panels each.

These arrays were deployed with a team of 14, covering the mechanical deployment crews, supervision and electrical DC reticulation.

- RTS Mark out and surveying

- Block layout, string line and bay layouts

- CHS anchoring and ground anchoring installations

- Maverick deployment using 10t telehandler

- DC reticulationfor 423 solar strings

- Connections to 2 x central inverters

- Compliance testing

- Commissioning

- Project engineering

- Scheduling and delivery planning